Le Gourmet Pro - les mijotés au goût du jour

Le Gourmet Pro - les mijotés au goût du jour

Tout le plaisir de la cuisine traditionnelle française en toute simplicité

|

Ajouter au panier

Le produit a été ajouté au panier Le stock est insuffisant. unités ont été rajoutées au panier Total:

|

|

Stock épuisé.

Produit bientôt disponible

|

|

Quantité minimum d'achat

La quantité minimum d'achat n'est pas atteinte

|

L’appertisation

L’histoire de l’appertisation

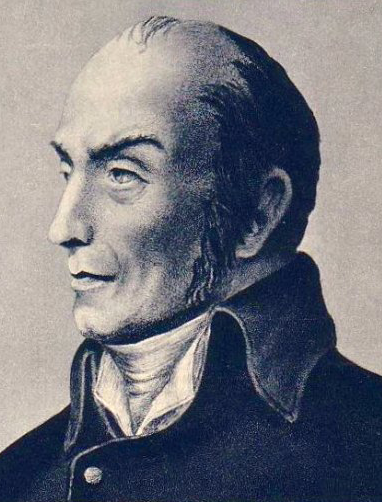

En 1795, Nicolas Appert découvre un procédé révolutionnaire de conservation des aliments.

Ce procédé porte son nom : Appertisation.

À la recherche d'un nouveau procédé de conservation des aliments, Nicolas Appert réalise ses premières conserves en bocaux de verre : la formule consiste à déposer un aliment (viande, légume, fruit…) dans un contenant hermétiquement clos et à le stériliser par une cuisson au-dessus de 100 °C.

Ce procédé porte son nom : Appertisation.

À la recherche d'un nouveau procédé de conservation des aliments, Nicolas Appert réalise ses premières conserves en bocaux de verre : la formule consiste à déposer un aliment (viande, légume, fruit…) dans un contenant hermétiquement clos et à le stériliser par une cuisson au-dessus de 100 °C.

L'appertisation est née.

Les conserveries françaises de sardines adoptent le procédé de Nicolas Appert.

A partir de 1815, la production de la conserve se développe en France et en Grande-Bretagne. Outre la sardine et les autres poissons, les viandes, les légumes et les fruits sont désormais appertisés dans des boîtes de conserve en fer-blanc.

Cette dernière est introduite en Australie puis aux Etats-Unis à partir de 1818. A partir de 1824, les conserveries de sardines se multiplient sur la côte Atlantique et d’autres professionnels de l’alimentation épiciers, charcutiers, confiseurs se spécialisent dans la conserve.

Le procédé de fabrication se sophistique peu à peu : les Britanniques Donkin, Hall & Gamble utilisent pour la première fois une étuve de contrôle pour vérifier la stérilité de leurs conserves.

C’est la naissance du « contrôle qualité ». En 1865, Louis Pasteur identifie les microbes et démontre que ces derniers sont détruits à haute température. Il souligne ainsi l’importance des découvertes de Nicolas Appert.

Le procédé de stérilisation par traitement thermique adéquat suffit à lui seul à détruire ou inhiber totalement les bactéries dangereuses pour la santé (salmonelle, listéria…), les micro-organismes, microbes, toxines ou enzymes et assurer ainsi la parfaite conservation des aliments.

Depuis son invention en 1795 par Nicolas Appert, le processus de l'appertisation est resté le même :

- Préserver l’authenticité du produit grâce à l’absence de produits chimiques, d’additifs ou de conservateurs.

- Stériliser les aliments dans un emballage étanche.

- Conserver à température ambiante et pendant plusieurs années le produit qui conserve son goût et ses qualités nutritionnelles intacts.

En règle générale, les vitamines sont préservées à 70% dans les produits appertisés tandis que les produits du marché peuvent perdre de 17% à 47% lors de la cuisson ménagère.

L’appertisation, garde-fou du risque alimentaire, est conçue pour conserver l’essentiel du frais et garantir une sécurité maximale des conserves offrant ainsi au consommateur toutes les garanties gustatives, nutritionnelles et sanitaires.

A partir de 1815, la production de la conserve se développe en France et en Grande-Bretagne. Outre la sardine et les autres poissons, les viandes, les légumes et les fruits sont désormais appertisés dans des boîtes de conserve en fer-blanc.

Cette dernière est introduite en Australie puis aux Etats-Unis à partir de 1818. A partir de 1824, les conserveries de sardines se multiplient sur la côte Atlantique et d’autres professionnels de l’alimentation épiciers, charcutiers, confiseurs se spécialisent dans la conserve.

Le procédé de fabrication se sophistique peu à peu : les Britanniques Donkin, Hall & Gamble utilisent pour la première fois une étuve de contrôle pour vérifier la stérilité de leurs conserves.

C’est la naissance du « contrôle qualité ». En 1865, Louis Pasteur identifie les microbes et démontre que ces derniers sont détruits à haute température. Il souligne ainsi l’importance des découvertes de Nicolas Appert.

Le procédé de stérilisation par traitement thermique adéquat suffit à lui seul à détruire ou inhiber totalement les bactéries dangereuses pour la santé (salmonelle, listéria…), les micro-organismes, microbes, toxines ou enzymes et assurer ainsi la parfaite conservation des aliments.

Depuis son invention en 1795 par Nicolas Appert, le processus de l'appertisation est resté le même :

- Préserver l’authenticité du produit grâce à l’absence de produits chimiques, d’additifs ou de conservateurs.

- Stériliser les aliments dans un emballage étanche.

- Conserver à température ambiante et pendant plusieurs années le produit qui conserve son goût et ses qualités nutritionnelles intacts.

En règle générale, les vitamines sont préservées à 70% dans les produits appertisés tandis que les produits du marché peuvent perdre de 17% à 47% lors de la cuisson ménagère.

L’appertisation, garde-fou du risque alimentaire, est conçue pour conserver l’essentiel du frais et garantir une sécurité maximale des conserves offrant ainsi au consommateur toutes les garanties gustatives, nutritionnelles et sanitaires.

|

Alerte

Veuillez saisir les champs obligatoires! |